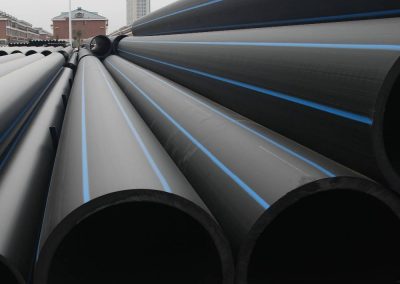

HDPE Pipe & Fittings (HIGH-DENSITY POLYETHYLENE)

High Standard Pipe Company manufactures High-Density Polyethylene (HDPE) pipes for municipal and industrial transmission systems. Our HDPE pipes could be utilized in many types of applications such as, potable water, sewer, drain, mining, irrigation, slip lining, and reclaimed water systems and are recognized in the industry for its zero leakage rate, high quality, high performance, and long life expectancy.

Our HDPE pipes are available in PE 100 & PE 80 Grade from sizes 20mm to 1000mm in diameter with nominative sustain pressure PN 4 to PN 32 conforming to international standards such as DIN, ASTM, ISO, PrEN, & ANSI Standards, and have been certified by international certification bodies such as AGS and QA International US and our Quality Management System is registered as per EN ISO 9001:2015.

THE BENEFITS OF HIGH-DENSITY POLYETHYLENE

HDPE has become the most popular material for pipe systems as it offers significant benefits compared to alternative materials, namely:

Low maintenance

Low Cost of Installation

Long Lifetime

High Safety Record

Easily Processed & Recycled

Low Maintenance – HDPE pipes retain their strength and functionality with minimum maintenance they are easily weld able into long sections, exhibit slow crack growth resistance along with resistance to rapid crack propagation and long lifetime in both static and dynamic loads.

Lower Cost of Installation – HDPE pipes are flexible, light weight and tough, enabling easier site handling and installation along with easier coiling into long lengths for easier handling and storage.

Long Lifetime – HDPE pipes can be certified to last at least 50 years and to withstand harsh terrains and climates with no corrosion. They exhibit excellent chemical resistance, abrasion resistance and good resistance to weather ability and UV along with resistance to micro organism and rodent attack.

High Safety Record and No Leakage – Weld ability brings leak free joints no over long distances, and the ability to withstand high axial and bending loads without joint failure. Chemical inertness ensures no contamination of water through taste and adore.

Easily Processed and Recyclable – Polyethylene as a thermoplastic is easily converted into various pipe and fitting dimensions and can be recycled in to less critical applications at the end of its lifetime.

WHY HDPE

High Impact Strength: The high impact strength of HDPE pipes compared with other plastic materials ensures a greater resistance to the severity of pipe laying conditions.

Damage Resistance: HDPE has low notch sensitivity, providing a high level of resistance to the effects of external damage, especially important for pipe bursting operations and others where there is likelihood of such damage.

Abrasion Resistance: HDPE pipes have excellent abrasion resistance providing long life in abrasive slurry applications. In most of these applications HDPE pipe outlasts other pipe materials such as mild steel and rubber lined steel.

Chemical Resistance: Outstanding resistance to a wide range of chemical reagents allows the use of polyethylene systems in applications such as: Tailings pipelines and chemical treatment applications.

Flexibility: HDPE pipes are flexible and can be bent to a minimum bending radius of 30 times the pipes outside diameter. This flexibility is critical in applications such as mine subsidence and earthquake prone areas. This inherent resiliency and flexibility allows the pipe to absorb surge pressures, vibration and stresses caused by soil movement.

Ease of Installation: HDPE pipes are easy to install with their light weight and long lengths. Polyethylene coiled pipes are widely used in applications such as stock watering, irrigation systems, communication, gas and reticulated water mains due to rapid installation and the ease and less frequent jointing.

High Flow Capacity: HDPE pipes have lower friction factors than most non-plastics materials. The surface energy characteristics of HDPE ensure that material deposition is inhibited and the smooth bore characteristic is maintained over the working life of the pipeline.

Long Life: HDPE pipes have a proven high reliability record across a wide range of industries and applications, now approaching a period of 50 years. HDPE also provides a long maintenance free lifetime with low whole life costs, compared to many other materials.

Recent Comments